Leslie Robert Potts talks about:-

A History of the seed factory

His work at the seed factory

House on the Horseshoe Pass

Ghost

The Start of the Seed Factory

Mr Clayton Russon, later Sir Clayton Russon, owned a small

seed and nursery firm at Goffs Oak in Hertfordshire, but was requested to move

by the Ministry of Agriculture and Fisheries as they were keen to move the seed

part of the firm away as it was only 18 miles from the centre of London. He

lived on an estate at Barmouth. It is said he was travelling home by train with

his wife when he spotted the derelict Upper Dee Mills. They got off the train

and went to the cottages by the level crossing to enquire. Charles Roberts lived

there and he said that it was he who persuaded them to buy.This was in the 1940’s

and during the war.

The company started out as "The Horticultural and

Botanical Association Ltd".

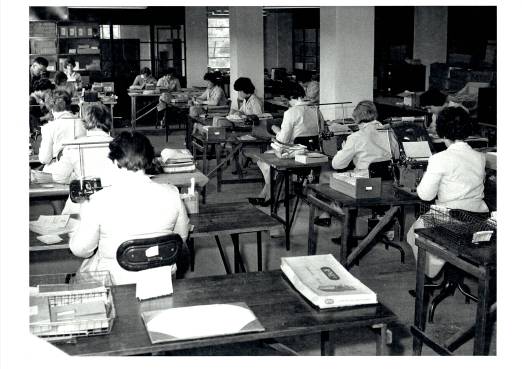

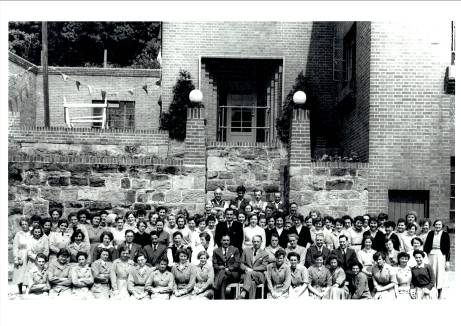

1985

All staff of HBA after our first fire drill

It became R & G Cuthbert after it was launched on the

stock market. The factory was needed as a result of the "Dig for

Victory" increase in the need for packets of vegetable seeds.

It started off supplying F.W. Woolworths Stores but in a very

small way, as the only habitable room was at the Wrexham end (seen to-day as a

room with a balcony, and was used later as the Chairman’s Office) this was

used as an office and seed packing area. He and his wife worked there initially

packing seeds.

When Leslie came in the mid 1950’s.

Mr A.C.Barber (Angus) was responsible for the buying of seeds,

bulbs etc., seed testing in our own lab and growing seeds to test at Abbey

Dingle Trials Grounds for germination etc.,. He and his team also answered all

technical mail and produced the Samuel Dobie seed catalogue. He ran the Dobie

shop and offices in Chester. Abbey Dingle greenhouses and fields with Dee Mill

Cottage were owned by the seed factory.

Mr A.G.Reeves (Bert) was responsible for warehousing, filling,

dispatch, maintenance and transport departments’ to-gether with wages,

production, Woolworth, Dobie offices. He was the contact with Woolworths.

These two gentlemen had shared accommodation at Abbey Dingle.

Leslie came to work for Bert, to run the Dobie Mail Order

Office, leaving a job in a shipping office in Liverpool and making the move to

Llangollen, aged 24 years.

The firm was growing and there were about 100 regular staff by

this time.

By now it was the second year of Dobies. On their first year

they had received and dispatched 38,000 orders. The second year Leslie’s first

year they had received and dispatched 68,000 orders plus thousands of items

advertised in daily and Sunday papers.

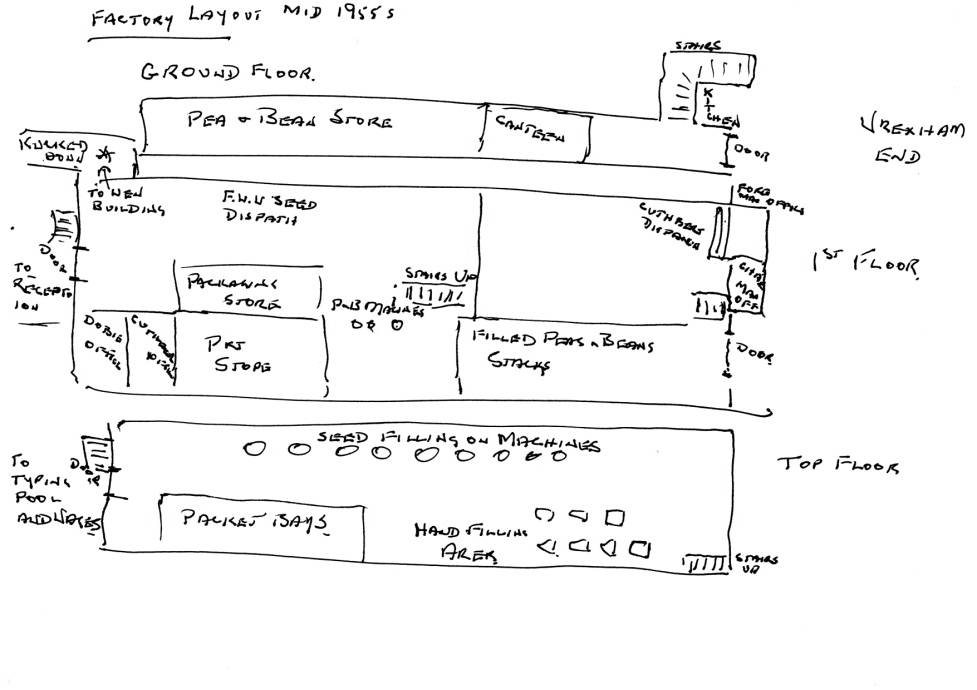

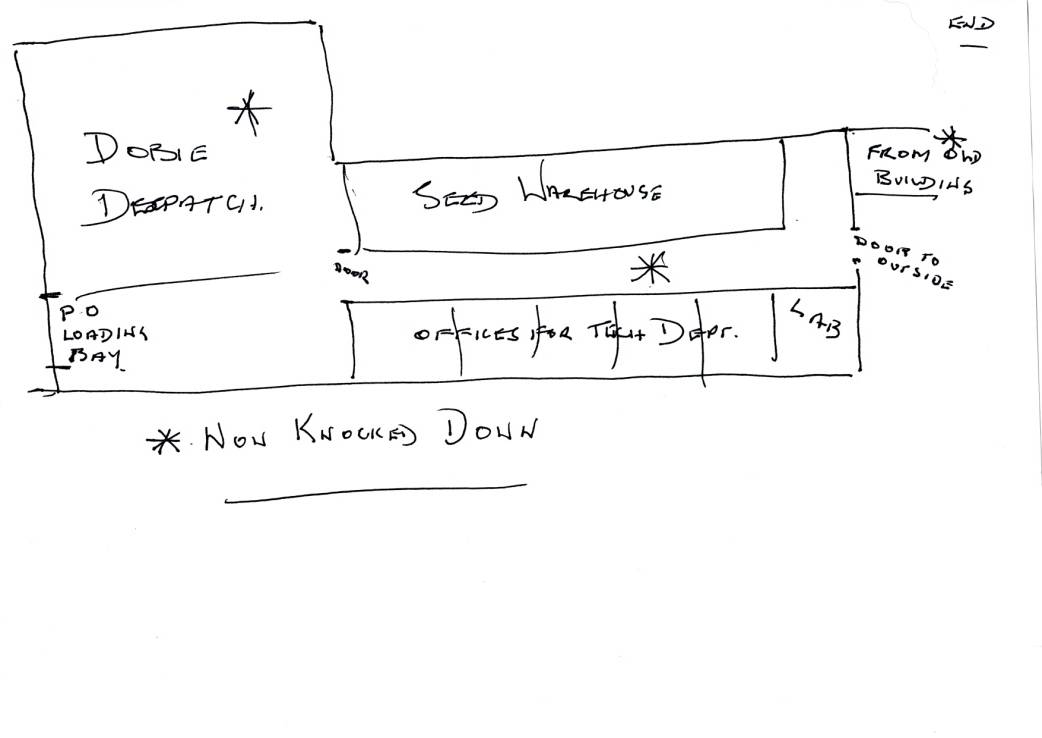

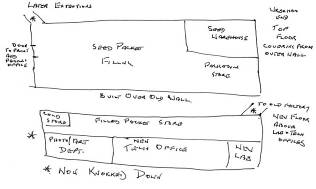

It was clear to see that Leslie could

visualise the factory, size and usage through its development and described the

factory in some detail. He will draw an outline drawing, but to indicate some of

the variety and extent of the business of its heyday, I will try to follow his

verbal tour through the building starting from the Wrexham end.

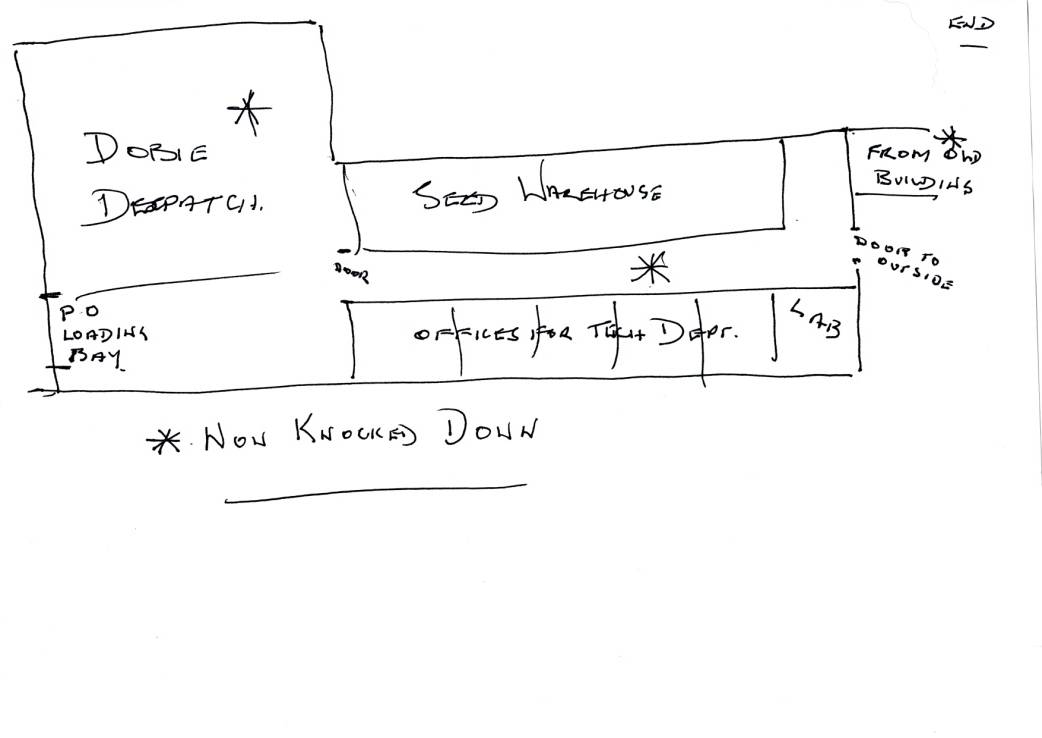

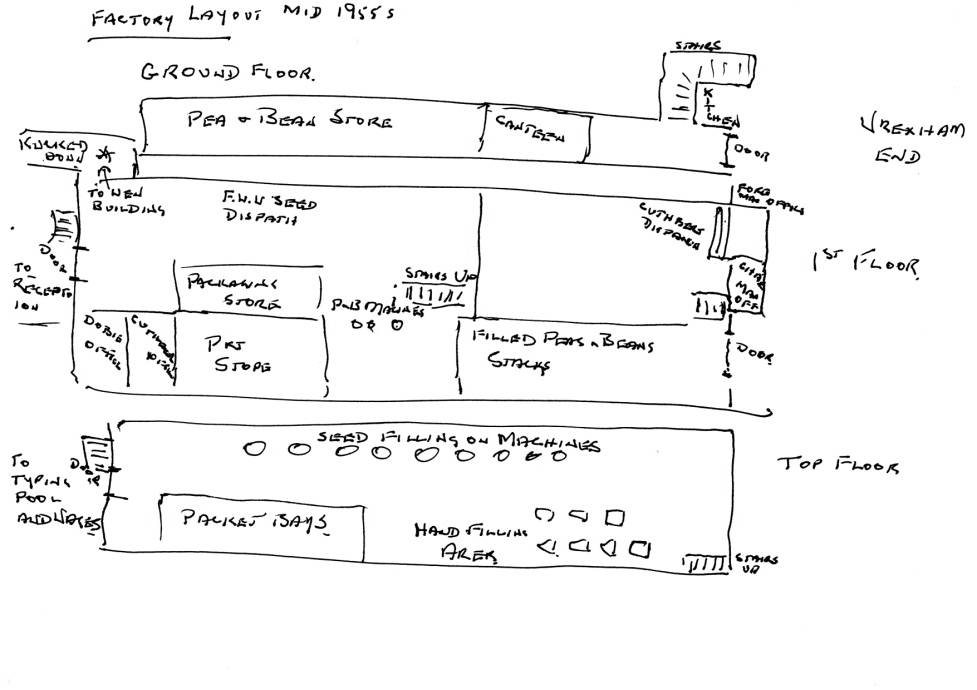

Seed factory mid 1950’s

Factory Layout mid 1955

Ground

Floor

Later Extensions

Double door, leading to canteen with Pea and

Beans(50k bags) stored behind Door on right (into the old turbine room) kitchen

fitted with two household stoves for supplying tea and coffee and warming soups

and pies brought in by staff.

Outside

By climbing stairs to first floor, through double doors you

would find the clocking in machine on right and also the foreman’s office and

on the left, the door to the Chairman’s Office. Through the door and down

three steps to single storey, gable roofed area; this was the Cuthbert dispatch

department. On the left (with outside double doors) was the goods inwards area

going forward was an area of packed peas and beans in corrugated cases stacked

seven foot high, forward again to three pea and bean filling machines all the

machines were made by Holier of Germany.

Above, suspended across the roof timbers and only accessed by

ladder was a store for practical items, light bulbs etc. This store collapsed

one morning at 8.05 am thankfully landing in the stacks of pea and beans. Leslie

at the time was talking to the supervisor in the new building at the far end. On

being fetched they rushed to the scene fearing the worst, but thankfully the

girls had past through the area by then. One man was underneath, George Edwards

but not badly injured. The problem was caused by heating the building ( even

with the greenhouse pipes) after a hundred years of no heating and a lifetime of

neglect the beams had dried out, shrunk and pulled out of the wall, the extra

weight of the storeroom didn’t help.

Further along was the empty packet store, the Cuthbert office

and Dobie office.

Turn right before the pea and bean machines you enter a new

two storey building. Steps up to the third floor on the right bring you to the

filling dept. On the left is a packaging area, on the right is the F.W.Woolworth

own brand dispatch area. Going through a door in front of you brings you into

the Reception area, Mr Reeves and factory managers offices. To the right the

stairs going up to the secretarial staff, wages and typing pool. Door on the

left takes you into to the filling area. On the left are the small packet

filling machines, on the right are the hand filling tables, girls fill packets

at these tables by weight, volume using scoops or splitting of volume or

counting each seed, some seed was worth more per ounce than gold The staff were

mainly women and many temps were employed during the season- January to Easter.

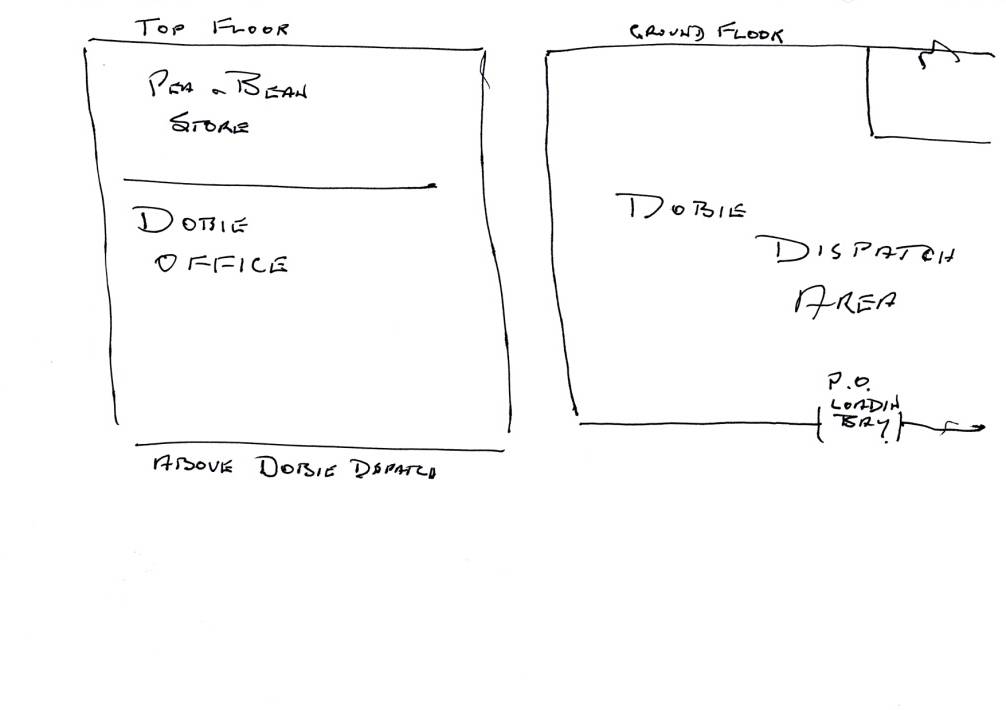

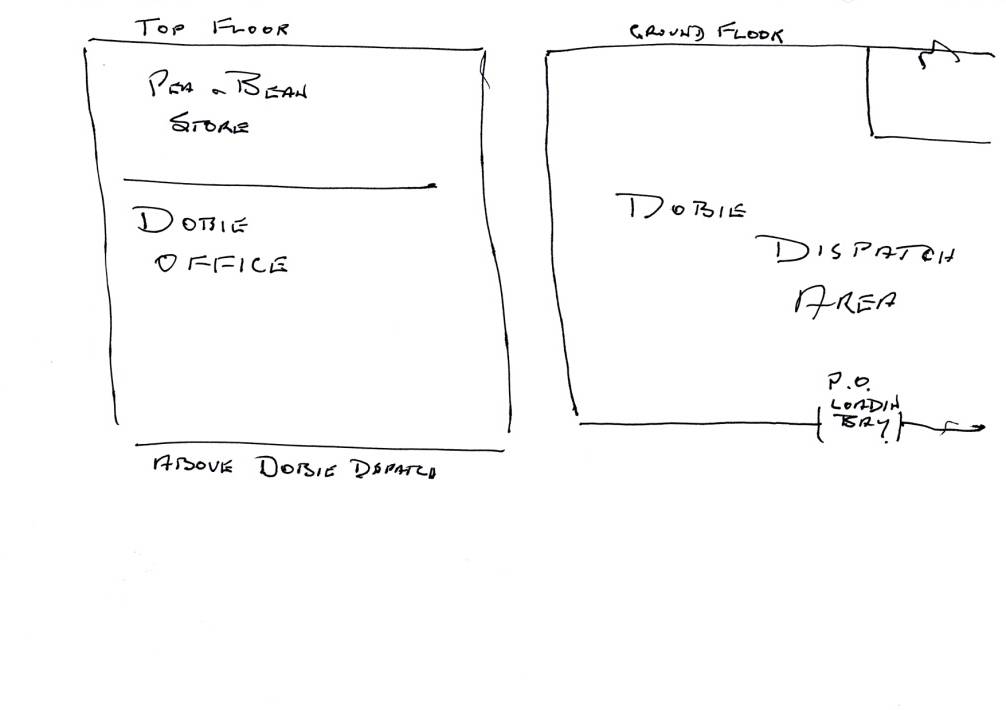

The new building held the seed warehouse on the right with the

new lab and offices for Angus and his team, then through double doors to the

Dobie Dispatch with a ramp at the end to allow the P O to collect the packets

and parcels.

Last extension-now knocked down

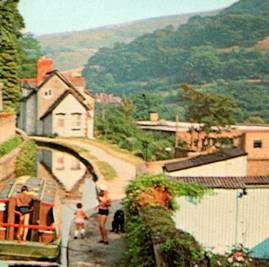

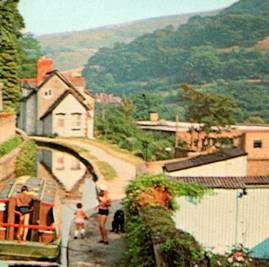

View of the factory from above on the canal towpath, with

the seed factory in the background-detail from a postcard

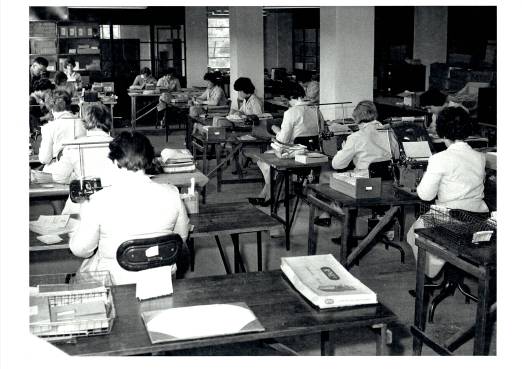

L.R.Potts, R.W.Manners and the Boots Buyer in Dobie Mail

order office at Mr Millers desk

Leslie’s job, for 11 years, was to run the Dobie Mail Order

Office.

He says that his new office, a previous lab, was very primitive

in comparison to his previous work place, not only making do with a hand filling

table and chair from Dobie dispatch, a Belfast sink as a filing cabinet, no

phone, and room shared with Dobie catalogues packed in brown paper which slipped

and had to be restacked most mornings before they could start work. Six girls

worked with him using adding machines, checking orders/item no/value. The typing

pool was upstairs, they typed acknowledgements and label sets ready for Dobie

dispatch. One of Leslie’s jobs at 6pm each day was to sign over a stamp on

every order over £2. At the end of the season he analysed the season to see

what improvements could be done for the next season. He introduced money saving

and stream lining methods and the second year changed the continuous stationary

sets; it involved less typing and increased the teams output by 100%. The office

equipment was folding wooden tables (which had to be covered in fresh brown

paper every Tuesday morning incase the Chairman came around). At the end of the

season we cleaned the tops and varnished them also putting plates across the

legs so they couldn’t collapse (during the season one end had gave way and the

table and contents collapsed onto a pregnant lady)

Dobie Mail Order Office, Out of season

The typewriters dated from 1909 to 1930 and with the hammering

they got were always breaking down, he had them serviced every Thursday but

spent a lot of time repairing them himself. He did get to buy a new machine a

year. Office hours were 9-6 but in the season he worked 8am till 10pm, staff 8am

till 8pm, his secretary till 10pm, taking her work from him between 9-10pm

catching the 10pm bus home. Out office staff came in to take letters during the

season. At the end of his time with Dobie’s they were getting up to 8,000

orders (each on average 31 items) dispatched plus adverts in his last year they

had 365,000 orders in the time from January till Easter.

Each year he took on temporary staff, but also school leavers

in September training them up for typing. The week before Easter Leslie would

have to negotiate how many he could keep as permanent staff. Then choose who

would stay. He said this was his hardest job, often having to reduce from

88(including temps) in the season to 16.

Leslie replied to every letter of complaint some funny or sad.

He mentions two of these.

One lady returned a badly damaged box "how would the

enclosed look on their lawn" She had received stainless steel milking

machine tubes.( split packet and repacked by PO in error) This was replaced with

lawn seed, but got a further reply complaining that he hadn’t admitted

responsibility for the error.

Another man wrote, one week after the order had been

dispatched to say it had not been received, so it was replaced with letter, his

next letter was sent to the MD. A further parcel with letter sent separately was

sent. A letter from his son was sent to the editor of a Sunday newspaper. He

sent another parcel registered, separate letter with copies to his son and

newspaper. His son went around to his Fathers house with Post Master and

Postman, after a search they found all the parcels on his bench in his green

house unopened.

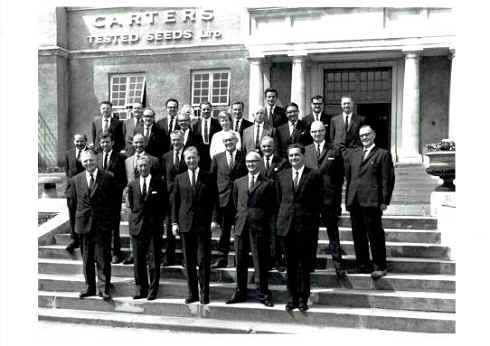

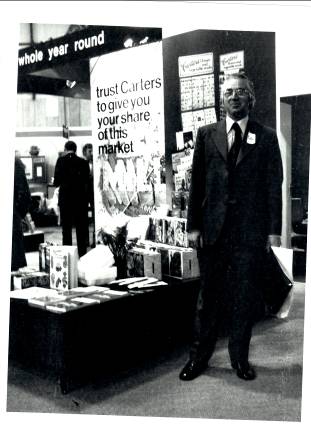

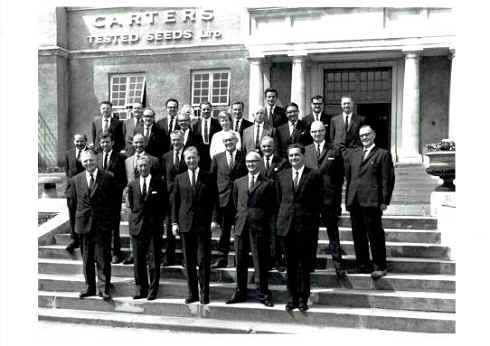

First sales conference of Carters at the Bryn Howell Hotel

In the 11 years working with Dobies the Group had bought many

seed and nursery companies including Carters, Ryders, Laxtons, Bunyards, Royal

Berkshire Seed and Wood & Ingram.

Mr R W Manners had joined the board in Llangollen to take over

the buying of all packaging and print. By that time Leslie was buying for

Llangollen and alsoresponsible for the purchase of gardening tools, chemical

etc.

He joined Mr Manners and started going around the Group to see

if we were able to streamline their requirements and standardise all packaging.

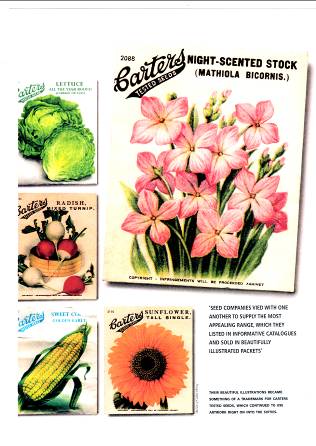

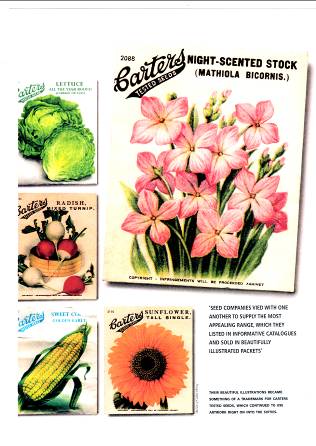

He remembers Carters:

Last sales conference of Carters-after HBA take-over at

Raynes Park

"A very elegant 4 storey building, complete with a frock coated plus top

hatted commissioner at the door". The firm was firmly set in the ways of

the 1930s and was very reluctant to face changes. They had a staff in the

printing department of 35.and were printing their own packets in single colour,

and hand making most of their envelopes. Carters had a range of coloured packets

and the Art Series packets were far beyond anything done in Llangollen, often

being printed in 15 colours, the only problem was it cost more to print the

packaging than they soldthe packed seeds for. That changed to 4 colours and the

Art Series was not reprinted.

Old Carters seed packets

Leslie was promoted to Manager Printing and Packaging Division.

New Packets

Les’s first award-

A mail order Rose Box

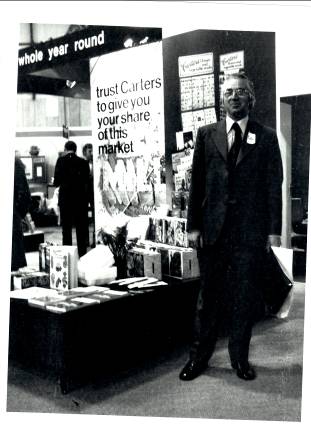

L.R.Potts on Carter’s stand of the first "Garden

Show" at the N.E.C

In about 1970 the Post Office went on strike for 6 weeks

starting in the end of January lasting for 6 weeks. This meant no orders for

mail order members were received or dispatched. Many tons of onions, shallots

and bulbs went bad and had to be taken to the tip. The Group went bankrupt in

the May of that year.

They were taken over by Rothschild’s. After a short time

everything was sold apart from Upper Dee and Lower Dee Mills and that was the

end of the Group.

A Chief Execrative from Rothschild’s was brought in, he

looked at everything we did in Llangollen and made many changes. Mr Manners left

the company to start Phostrogen in Corwen. A new packet was designed by

consultants for Carters; using all new painting and text. No black was used,

replaced by brown with a 10% yellow background making it very difficult to

print. Many awards were given for this design but after 3 years it was replaced

by normal designs as no one was buying them.

We were then passed on to the Petro chemical industry and

became a very small cog in a big wheel, finally being sold as part of a brand.

After the deal was done the buyers were told about us; they put us up for sale

and Suttons (then owned by Volvo) could afford us and closed us down regardless

of the promise made.

HBA had tried to buy them 18 years before but had been stopped

by the monopolies board.

Leslie at home

When Leslie first moved here he lived with his sister at

Tan-y-Bwlch. After this he rented a farmhouse, Oernant Isa in the village of

Oernant, The farm belonged to Mrs Gollan of Prentredwr. The farm was used for

sheep farming (John Piggot).

The village, once a collection of farms, smallholding and

about 12 quarrymen’s cottages, to-day only the farm and 3 cottages remain

though many footings remain (on the top bend of the Horse Shoe Pass). The

village was there before the Horse Shoe Pass was built; the nearest shop was at

Pentredwr.

Remains of the village of Oernant as you can

see them today - 2010

At the top of the Pass was the Westminster Quarry (Blue Pool).

Many walked from Pentredwr, Rhewl. Llantysilio etc to walk every day for work.

Others stayed in the barracks (approx 600 men) on site Monday to Friday.

One of the tales told to Les was "every Friday the owner

of the quarry lunched at the White Swan pub in Pentredwr before going in his

trap and driver up the bwlch (the old pass) with the wages to the quarry. The

men posted a boy on the mountain above the village as look out, unfortunately on

day the choice of venue for lunch was the Britannia Inn. The trap and driver

carried on for lunch at the Swan, and when he had finished he put a stick with

jacket and hat around and went up the Bwlch meanwhile the Boss walked up the

footpath to Oernant and over the top to the quarry and found the men sat around,

playing cards etc. The boy dashed in too late and some men lost their jobs.

After a couple of years Leslie his wife Joan and their son

Allan moved into Ty Isa at Oernant. This had been a holiday cottage for years.

It had been two cottages knocked into one. The left hand one also had a stable

at the back in the past. Leslie assumed he provided a horse to work on the

tramway, bringing the slate down to the top of the incline above the Britannia

Inn. The other worked in the quarry as did most of the men in the village. The

quarry above the village, records have never been found of who owned it or

worked there. John Hawkes owned it in the last century but never worked it, if

you look in the bottom you will see the remains of a building, he was told it

was used as a shot tower in the First World War.

Leslie modernised the cottage, levelling the two floors 14inch

difference between the two. The slate waste was removed until he saw he was well

below the walls. After a sleepless night not sure whether he would still be in

bed by the morning, he and his wife mixed and laid seven tons of concrete by

hand the following day and hoped they were safe. He removed all the old horse

and lime plaster and set about getting the walls, doorways and windows straight

but he just followed the curves as they were in some places six inches out,

doors and window were square. The walls were plastered with a waterproof

additive, much to the irritation of the plasterer, as his pink finish wouldn’t

stick.

The house was cold even with stoves in both cottages on 24

hours. Water was collected from the stream, and if left overnight a few feet

away, it would freeze. Lighting was by oil lamps to start, but a diesel engine

with a dynamo soon gave plenty of lights around the place and charged batteries

and enough power for a TV. The Lister engine was fitted with two 2foot

flywheels. To start it by hand could be hard and needed cranking and care. His

uncle’s friend was appalled at his wiring and set about fixing it, after many

hours the man asked Leslie to start the engine, fixing one wire to a terminal he

attempted to do the same to the other, there was a large flash leaving him with

just the insulation in his hand, fortunately Leslie’s father worked in power

stations and the cable he was using was 50 amp. Leslie was left to rewire it all

again after taking them back to Liverpool. One time his uncle was incensed that

a woman could start the engine so he tried, it lifted him off the ground 2 foot

in the air. Many things happened at Ty Isa over the 5 years they were there but

the crashes on the corner above them put the end to their stay.

The Ty Isa Ghost

On a moonlight night they would hear steps crossing the slate

slabs outside and would watch as the original front door of the right cottage

opened. Later on they built a porch over both doorways, but still it was only

the original door that opened. They had a very large black dog scared of no man,

but this Alsatian would back away and hide under the stair well at the back of

the cottage, a quivering wreck. One night, in frustration, Leslie took his dog

and a big torch down the path. Nothing was to be seen, but the dog had run

indoors and was hiding, shivering in the stair way.